When we talk about movements, attention tends to focus on the Swiss, which is understandable, but excludes some of the biggest movement manufacturers. Seiko, Miyota and Co., not to mention the Chinese, produce far more movements per year than, for example, ETA or Sellita. To put this into some perspective, Miyota produces three movements per second! What's also amazing is that Miyota holds a Guinness World Record with its quartz caliber 2035 and produced an incredible 1.7 BILLION examples by the end of the 1990s. It is still in production today and has significantly exceeded a total production volume of 5 billion in its 40+ year lifespan. With this in mind, and with the opportunity to take apart a Miyota 9015, I'm championing a movement that has become a true cornerstone of the industry, while taking one apart for a closer look.

Miyota's mechanical lineage

As part of the Citizen Group, Miyota is one of the world's largest watch movement manufacturers. They produce both quartz and mechanical movements at amazing speeds. Miyota's origins date back to 1959, when Citizen established a watch movement factory in the city of Miyota, Nagano Prefecture, Japan. The company became an independent name in 1980 and produces quartz and mechanical watch movements for Citizen Group and third parties. And with almost 70 years of experience, Miyota has become a true expert! The company's main factory, now located in Saku, Japan, employs just over 200 people and has an almost fully automated production and assembly line for solar, quartz and mechanical watch movements.

Miyota is also known for several innovations in movement construction, including the Parashock shock absorber system as well as AO-Oil and AO-Grease, long-lasting, corrosion-resistant lubricants. The movements are also manufactured entirely in-house, right down to the winding and hairspring, which will please many. This means that every step in production is optimized and controlled, which is reassuring.

Miyota's catalog of mechanical movements is divided into the 6T, 8000 and 9000 caliber series. Miyota's journey into mechanical watchmaking began with the 6T series in 1969. This was followed in 1975 by the Caliber 82, which became one of the most widely used mechanical movements in history. This evolved into the automatic movement 8205, which was introduced in 1986, and finally the caliber 9015, which came onto the market in 2009. And it doesn't stop there: in 2017, the company introduced the Caliber 8315, which offered a longer power reserve, and in 2021, the Caliber 9075, an automatic Flyer GMT movement.

Caliber 8315, from the Miyota 8000 series

Caliber 8315, from the Miyota 8000 series

To break things down even further, the 6T series is a family of small calibers measuring 8 3/4 lines (19.74mm) wide. The 8000 series is a range of full-featured mechanical movements with a standard finish, while the 9000 series is the premium line based on the same architecture as the 8000 series. However, there are some technical differences, such as: B. the possibility of hand winding and a higher frequency in the 9000 series. The 9000 series is also slimmer and uses a different ball bearing for the central rotor to reduce noise and increase stability.

Both offer a range of features, from pure time displays to full calendar views, and from open-heart layouts to fully skeletonized ones. Depending on the specific movement within the 8000 and 9000 series, the size is either 11 1/2 lines (25.94mm) or 13 1/2 lines (30.45mm). This means they meet industry standards and represent a solid alternative to Swiss-made counterparts (ETA 2824 or Sellita SW200).

Now let's get to actually dissecting one of her moves!

The collapse

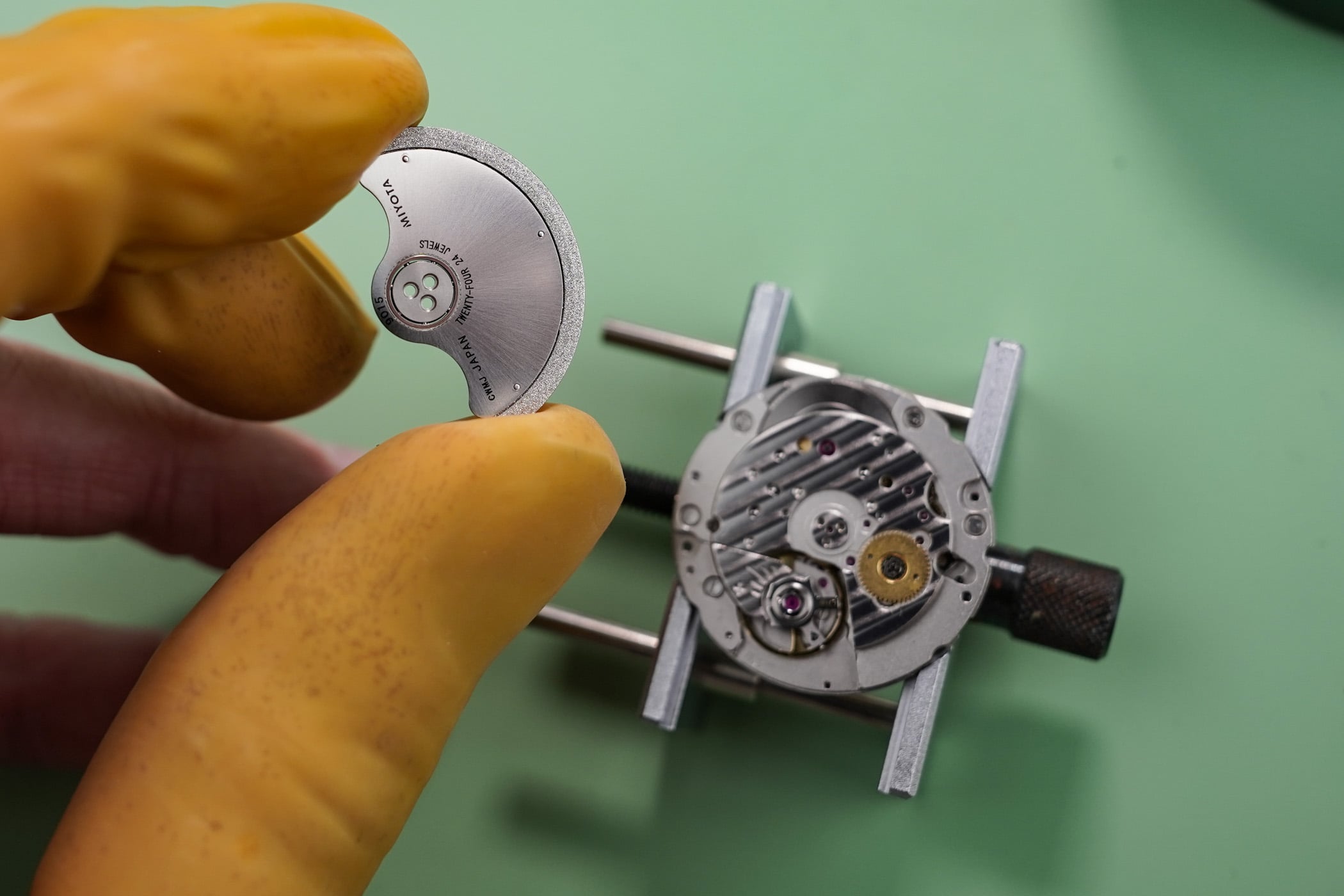

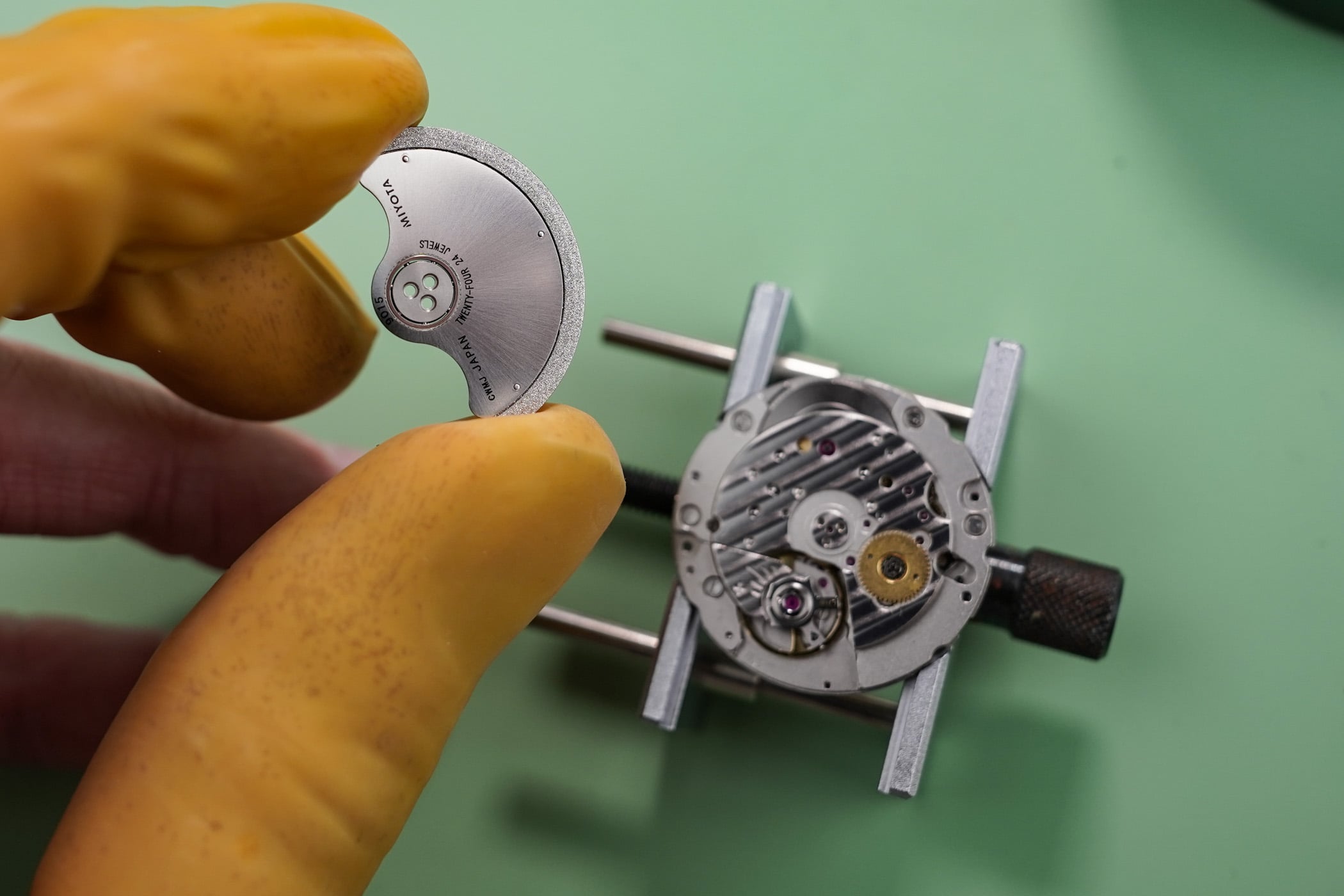

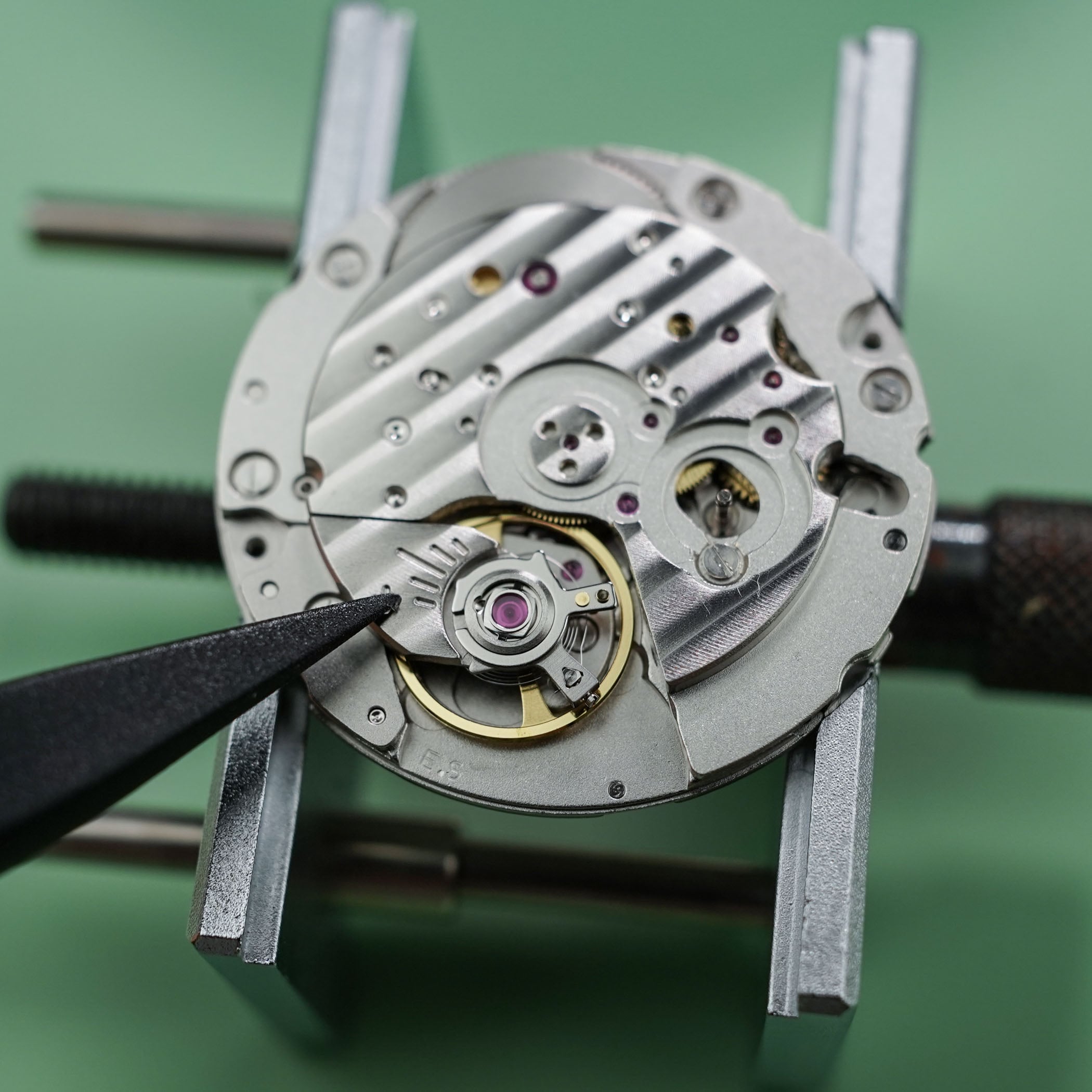

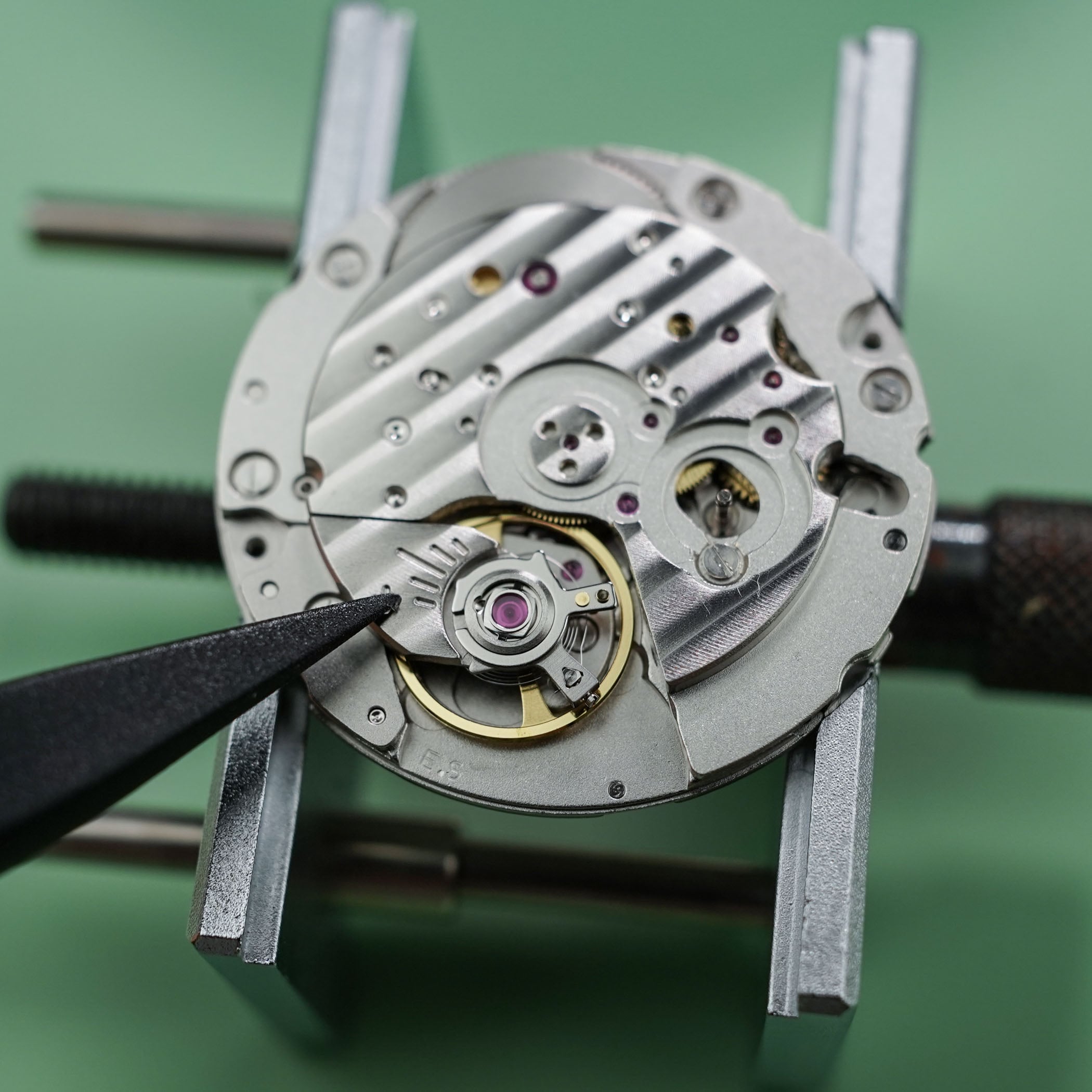

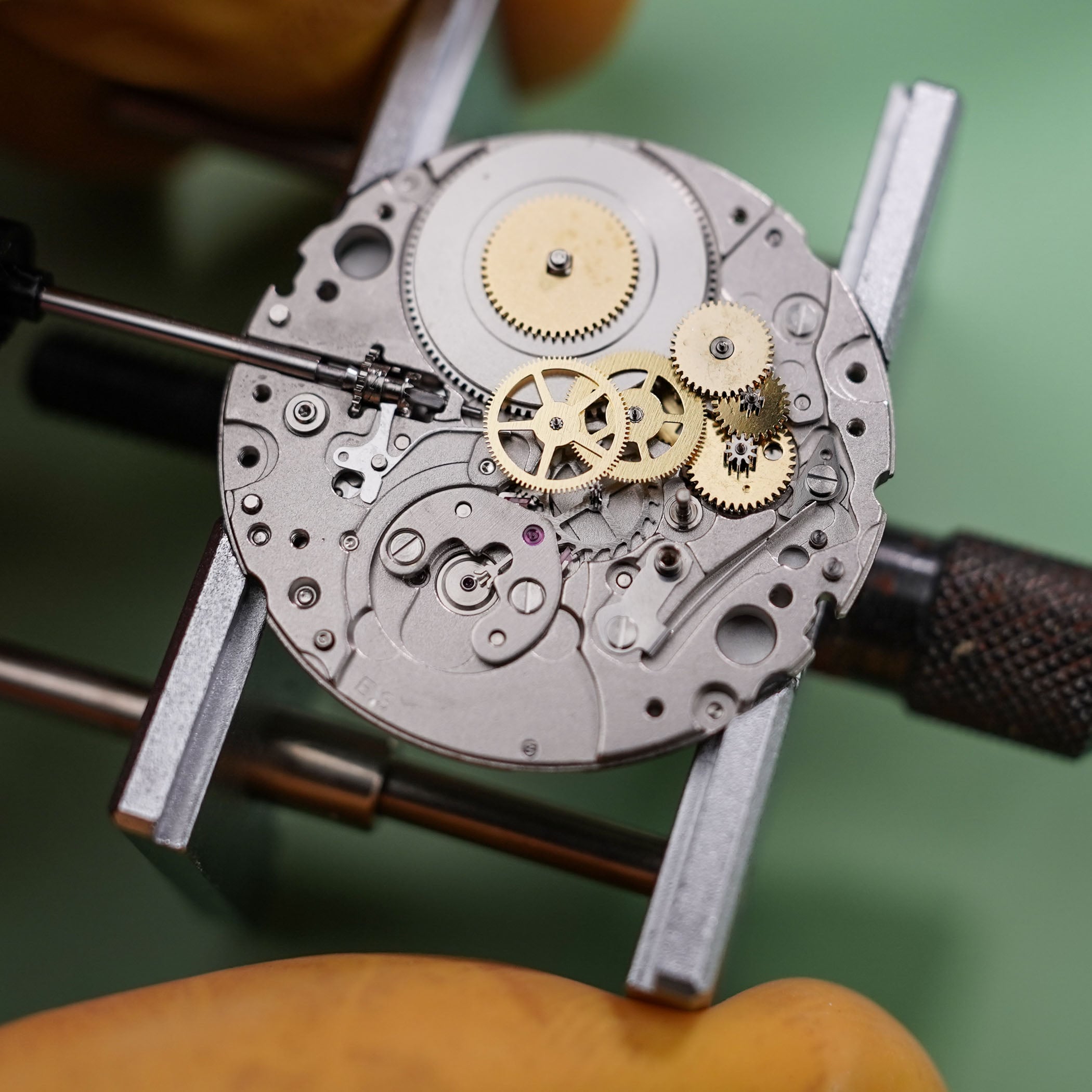

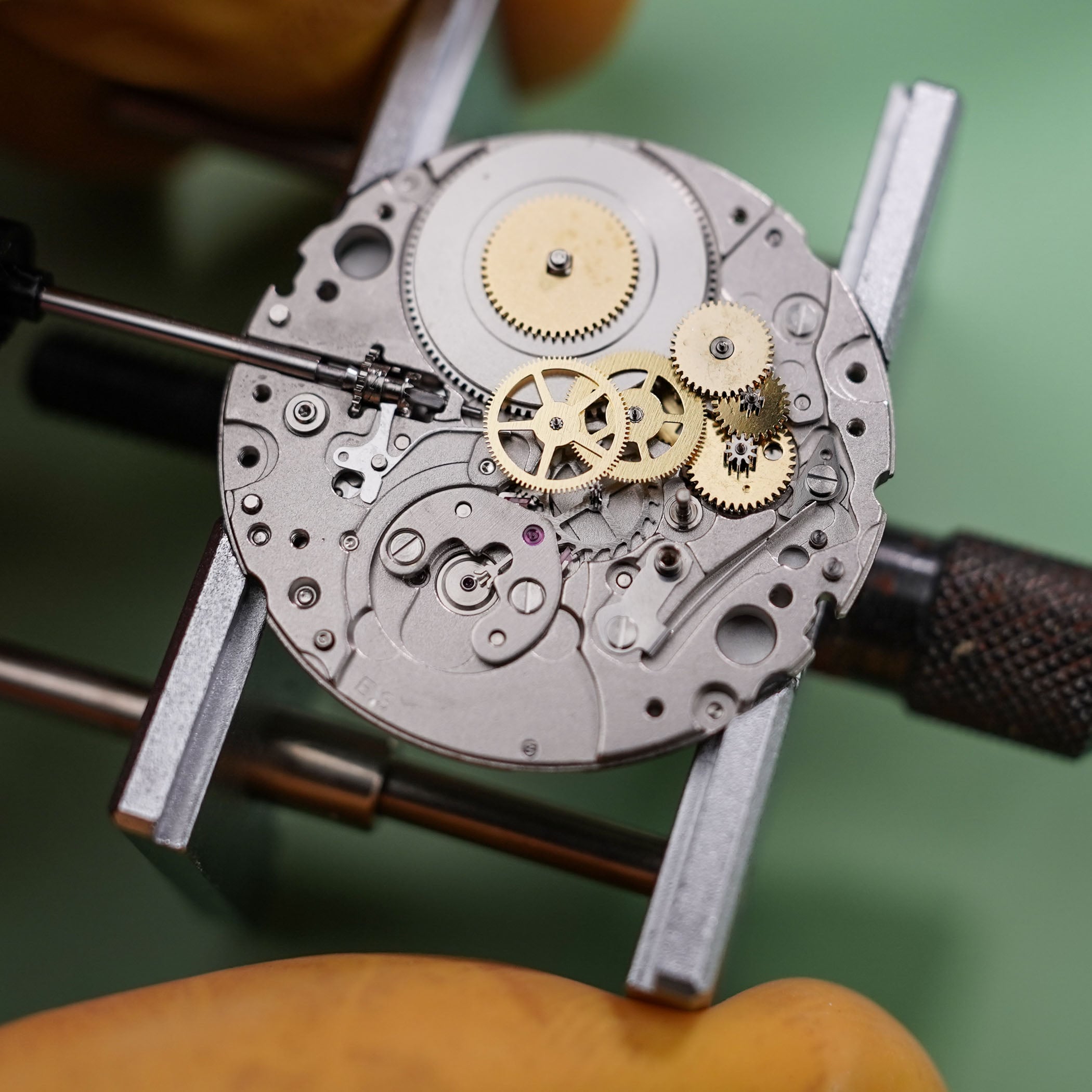

Dismantling the movement begins with removing the crown shaft and then the central rotor, which is secured with three screws and a central ball bearing. What immediately strikes me is the difference from some other staples in the industry, such as the ETA 2824 and the Sellita SW200, both of which feature a single central screw.

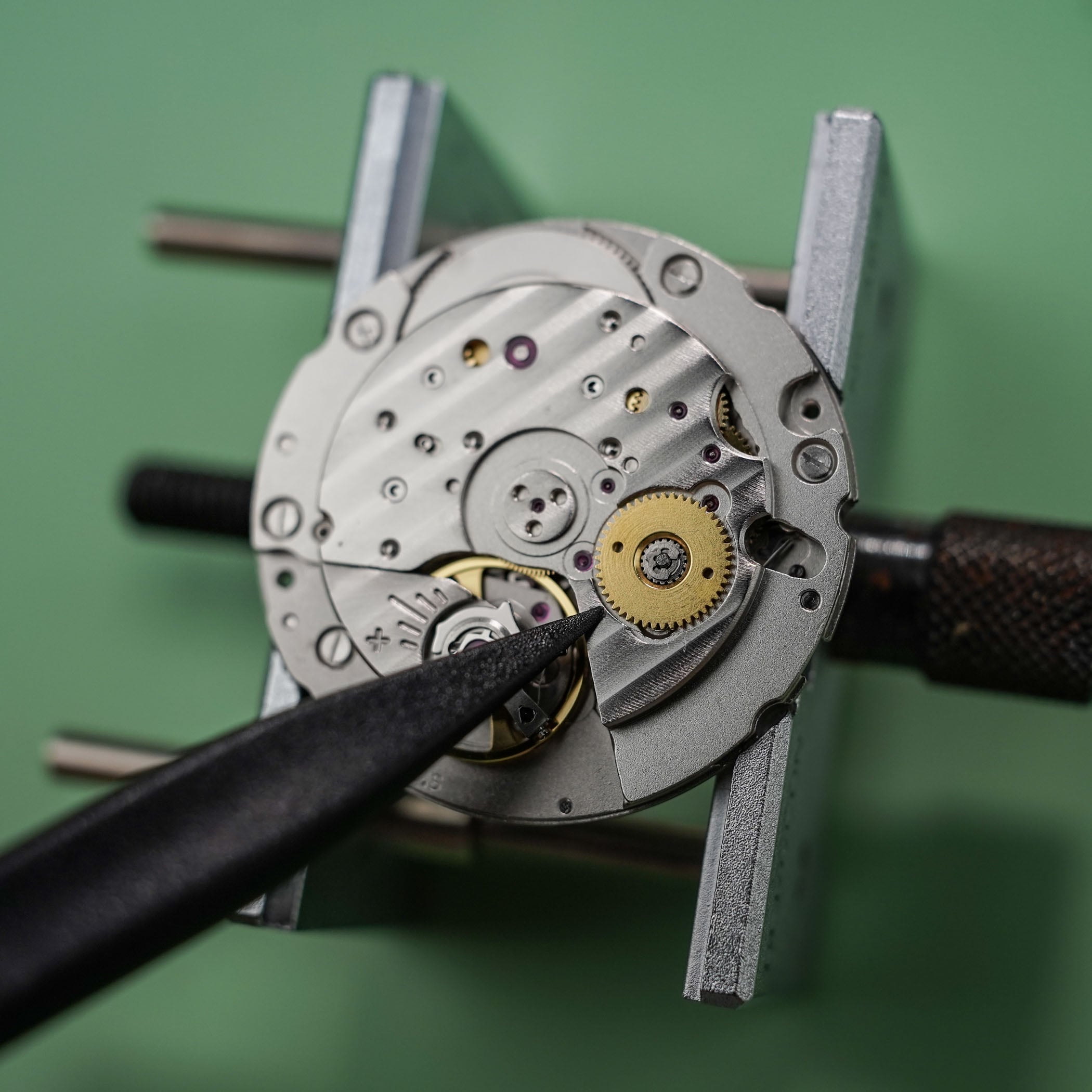

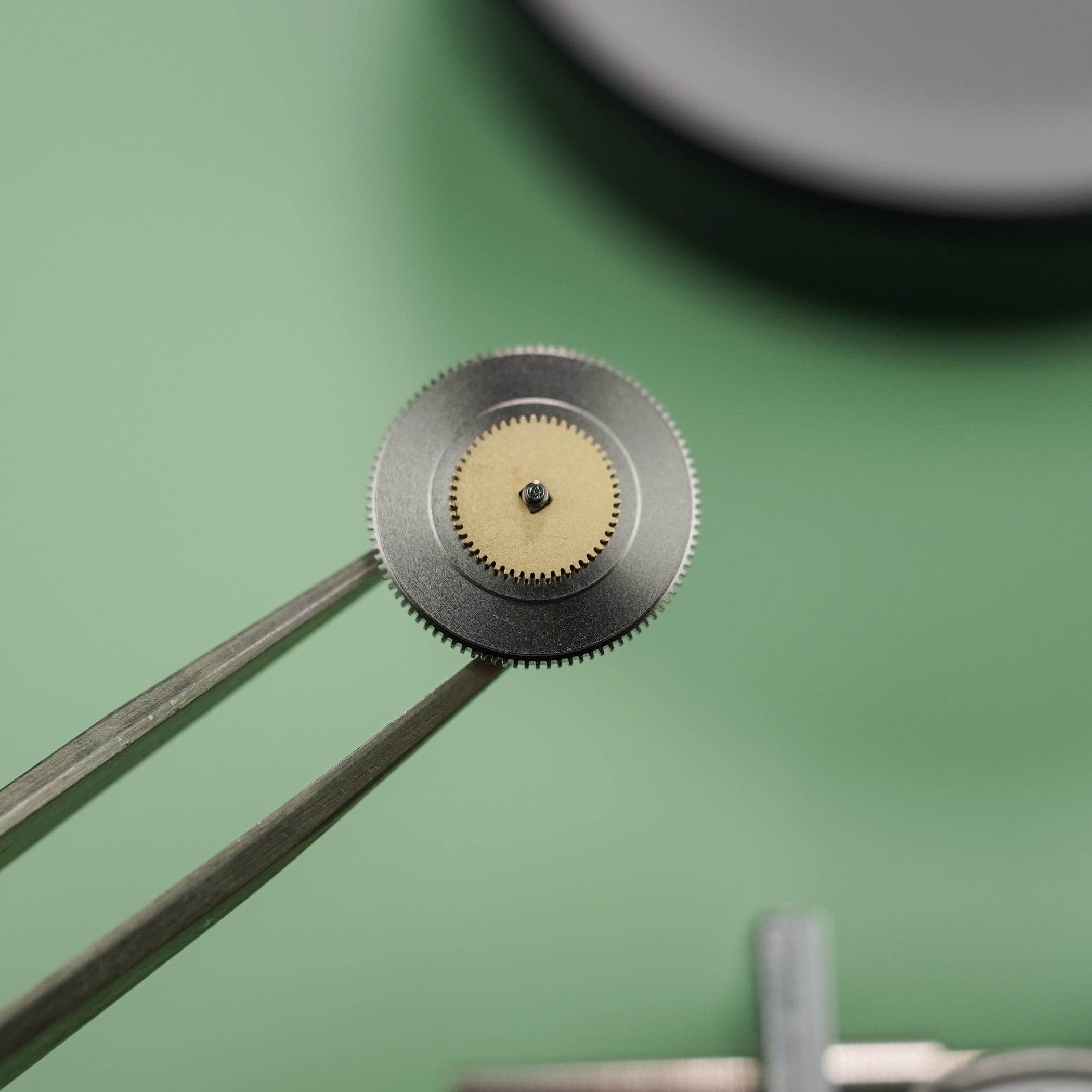

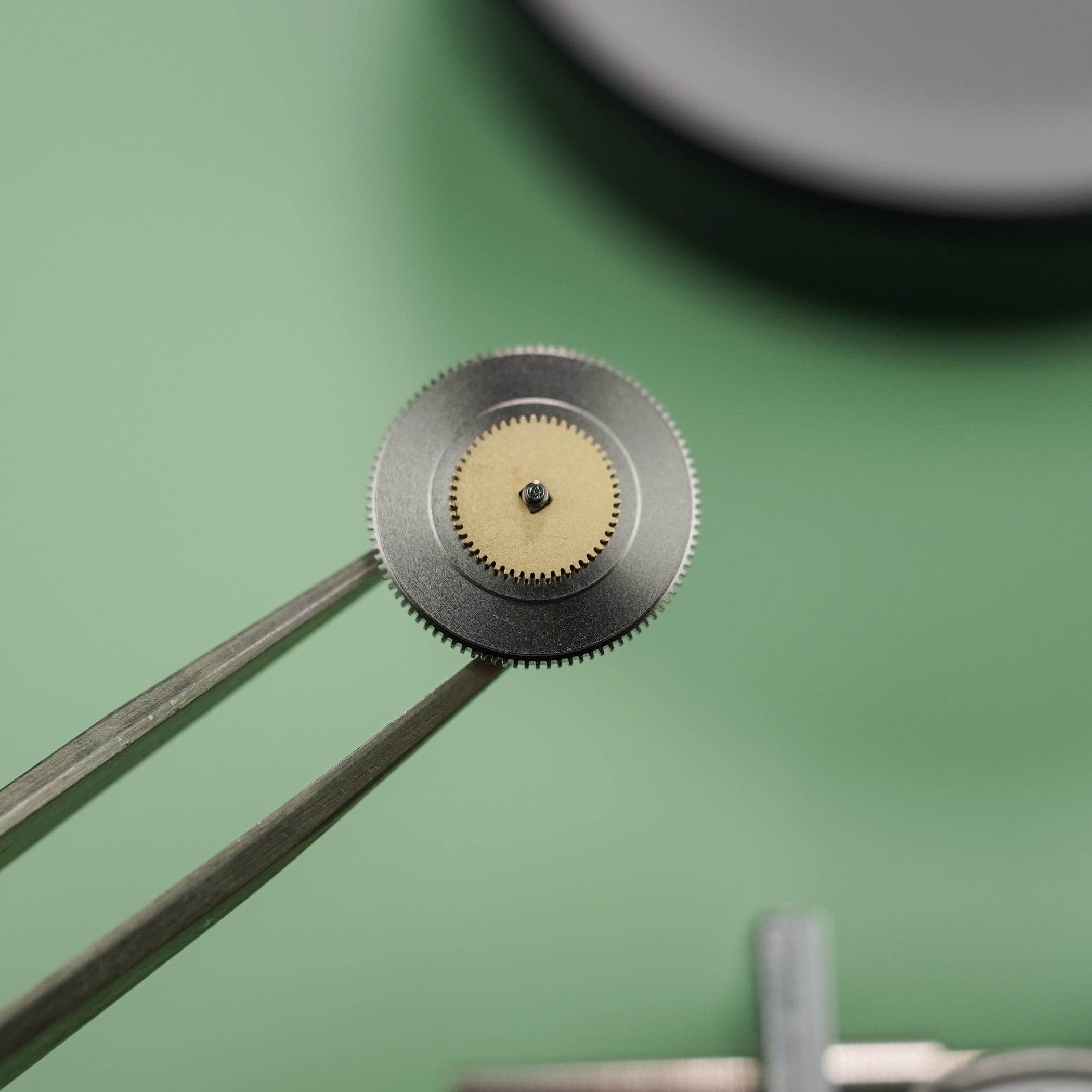

Below you can see a single directional wheel for the winding system, as opposed to the bi-directional twin wheel system on the ETA and Sellita calibers mentioned above. This means that when the rotor turns, the movement is only wound in one direction. When running in the other direction it rotates freely, which is why MB&F decided to use it in the MAD1, for example.

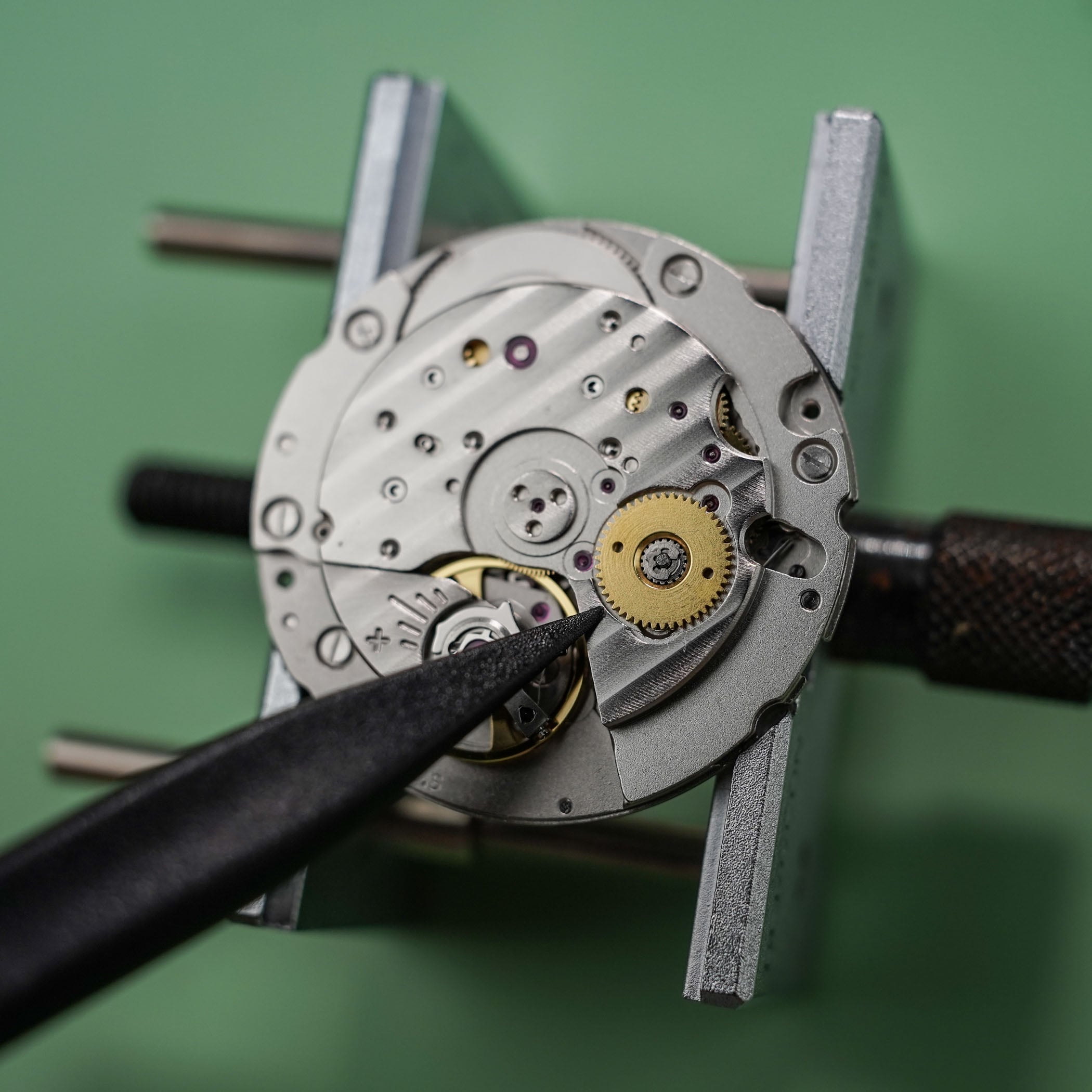

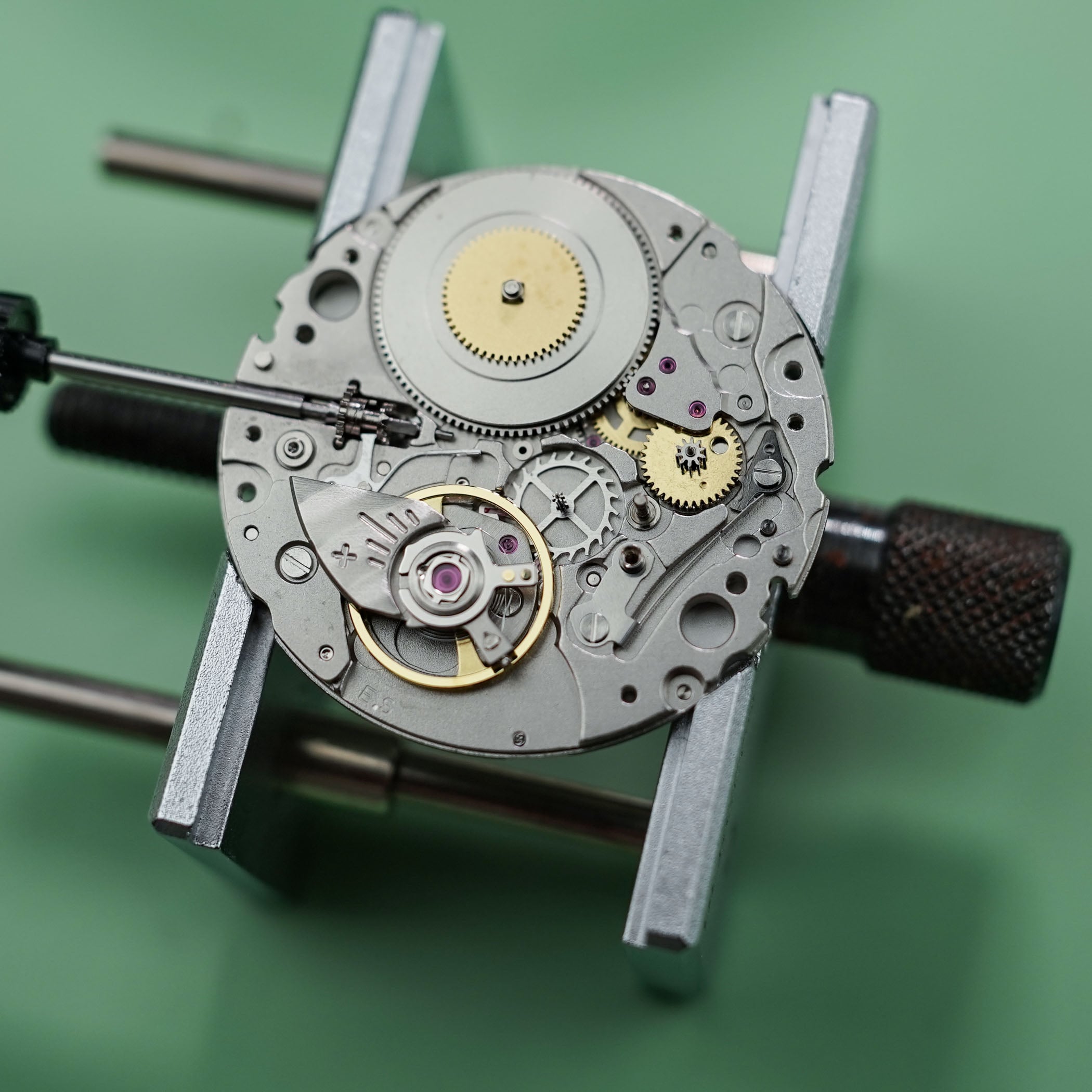

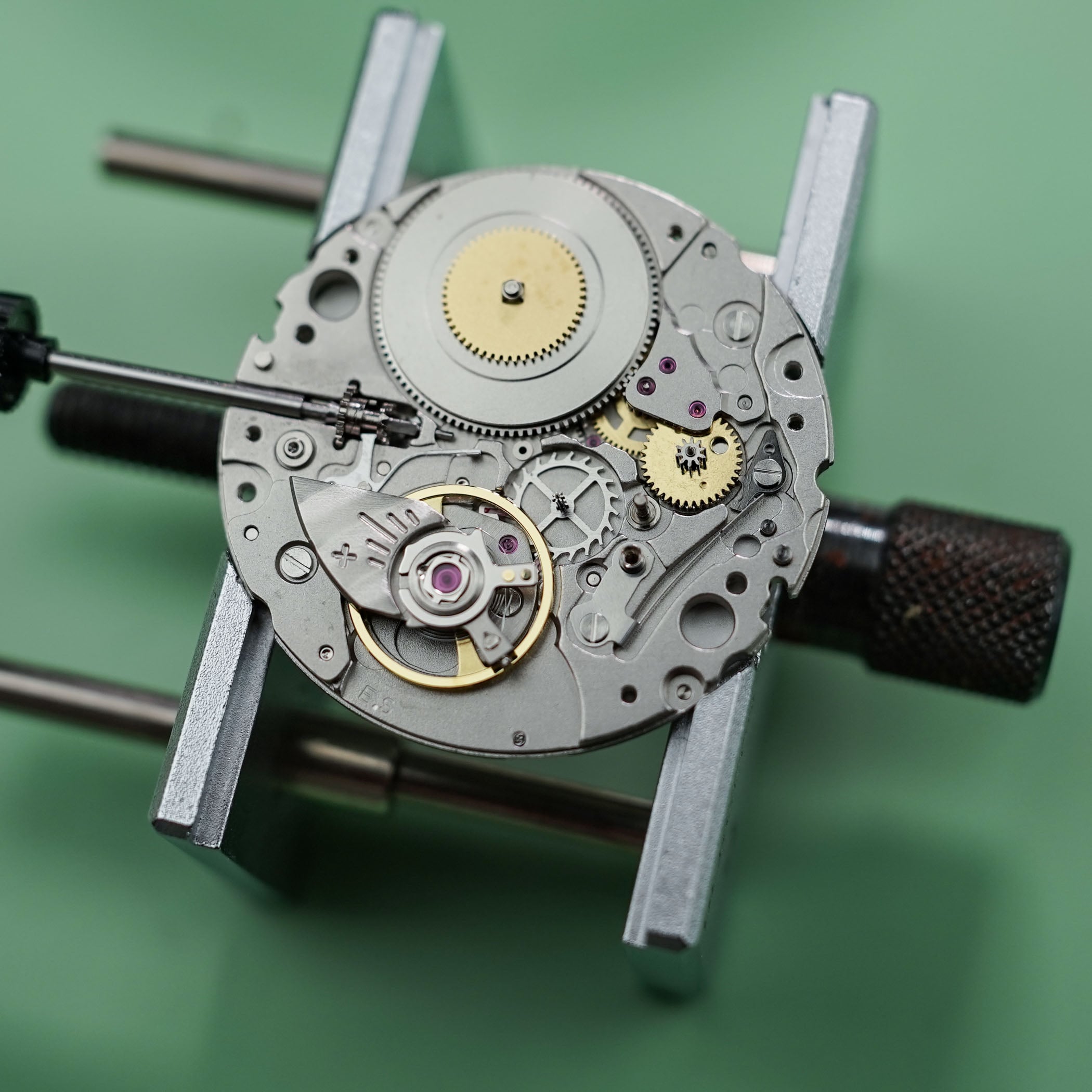

I go ahead and take off the top three-quarter panel that holds many components in place. As soon as I do this, almost the entire running gear from the barrel to the balance wheel is exposed:

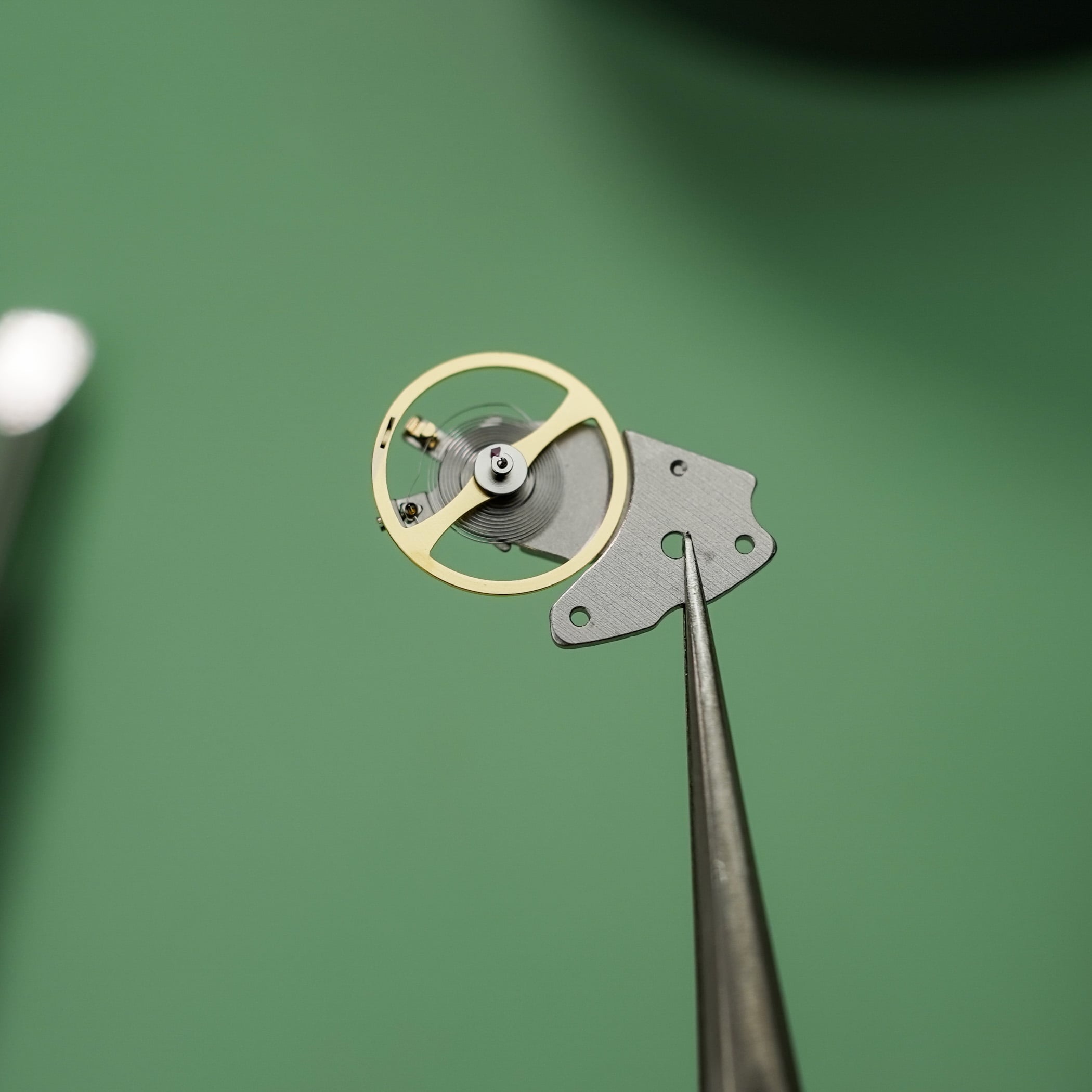

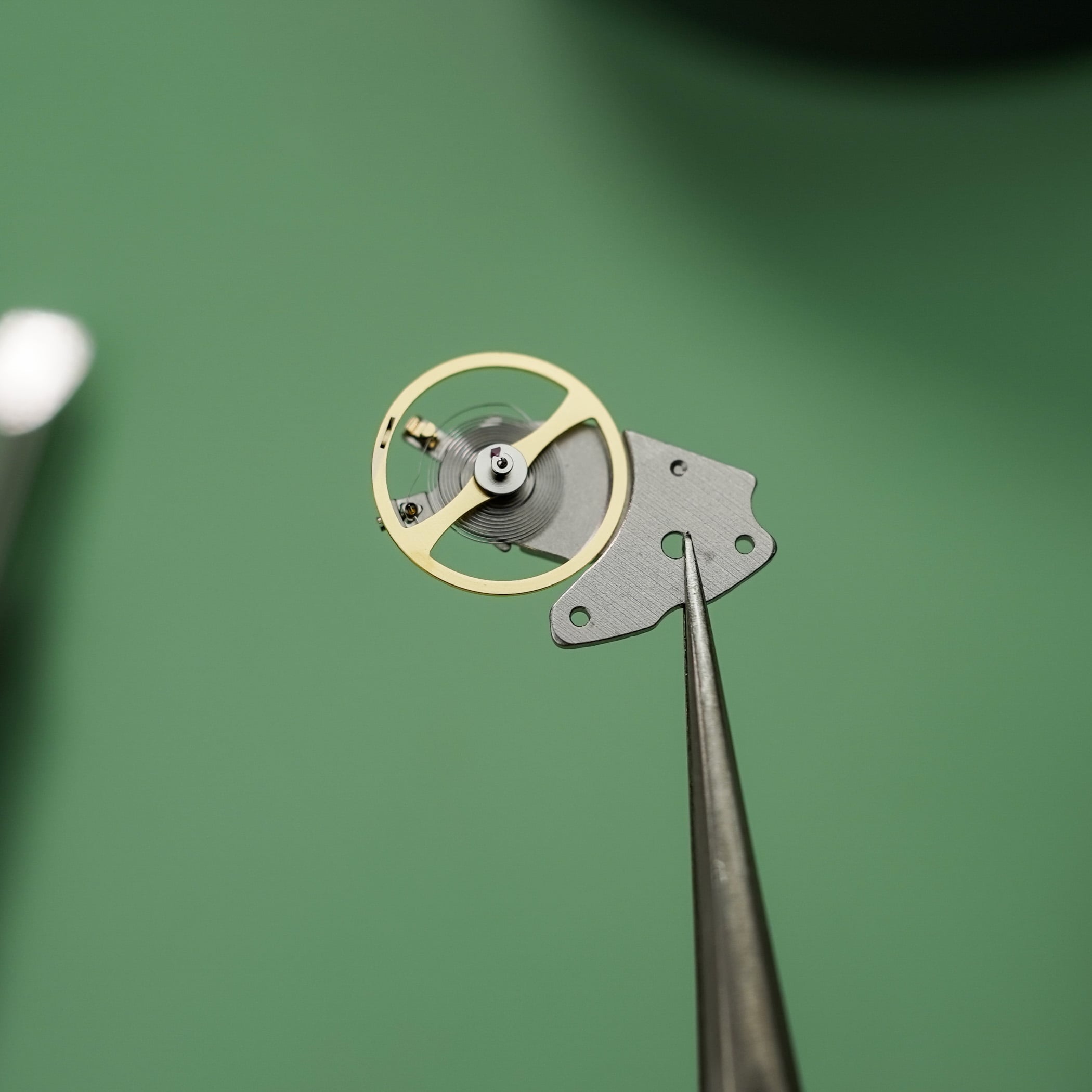

Little by little I remove the entire balance unit, the idler gears, the third wheel and the third wheel and so on. What is striking is the Parashock shock absorber above the balance shaft, a development by Miyota, and how it can be regulated.

Where you would expect a fine adjustment system like a gooseneck or an A-arm balance screw, there is none of that here. Instead, there is a plus-minus scale with adjustments on the edge, where the spiral bolts are also located. It is a practical solution that helps with manufacturing and assembly.

As you progress, you can also see the brake lever for the second hand (the stop-seconds mechanism).

With all that removed, I can turn to the other side of the movement, where there is more to discover. First I need to remove the hour wheel guard to reveal the date disc and date bridge. Then you can also see the dial and lever that moves the date disk in one direction but moves out of the way when you turn the crown the other way.

This is about how far I dared to go with my admittedly rather limited watchmaking experience and skills. Putting everything back together is a little more challenging, especially the barrel and gear train bridge, which requires the perfect alignment of a variety of parts.

More details than expected

My main takeaway from all of this was the quality of the movement. I am aware that Miyota's 9000 series is positioned as a premium model, but it is still often perceived as unfinished or at least very simple. While this is true compared to handmade movements, the finish was honestly quite surprising to me. There are some sophisticated elements, even in places where functionality is not important. There are the beveled edges on the worm disks, the sharp ribs on the bridges and plates, the matting on all sides of the rotor's flywheel, the perlage on the hour wheel cover (caliber 90S5) and so on.

Then there is the scale at which Miyota's movement production is carried out. The production takes place on a large industrial scale and is in no way comparable to artisanal watchmaking, but also requires manual work. For example, the end curve of the balance spring is formed by hand. But neither ETA nor Sellita's production methods can do that. However, the level of precision required to produce movements reliably and cost-effectively, as well as the speed at which Miyota produces, is incredible. The fact that Miyota is outperforming even industry giants like Seiko is amazing to me and puts a new perspective on things.

And then the true attention to detail and a surprisingly high level of workmanship adds to my appreciation for Miyota and its 9000 series movements. With it and other movement families, Miyota offers an impressive range of functions, backed by decades of expertise that result in reliability, ease of maintenance and repairability, all at a very fair price. And all of this at a level that the Swiss simply cannot keep up with…

For more information, visit miyotamovement.com.

https://monochrome-watches.com/miyota-9015-automatic-movement-deconstruction-history-miyota-manufacture-technical-perspective/